Crucible Care and Use

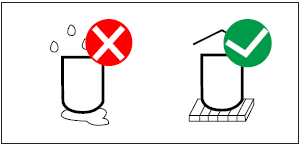

Store crucibles in a dry, warm area.

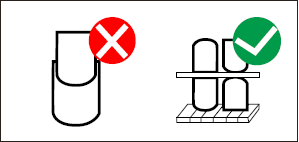

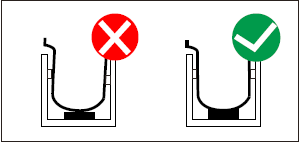

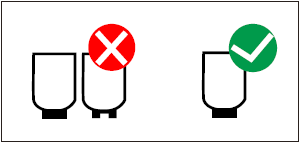

Do not stock inslde another.

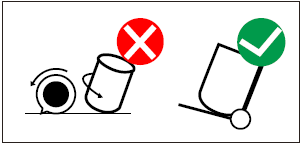

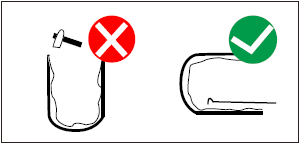

Do not roll crucibles.

Use a Ceramic fiber Blanket to seal. allow space between top and sides of furnace

Use locating bricks in tilting furnaces,to allow for expansion.

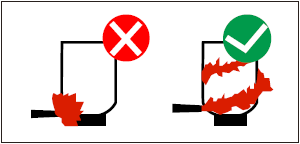

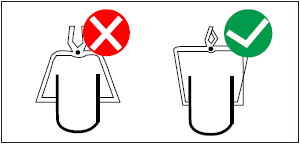

Tangential fire around Crucible.

Only add flux after metal is molten

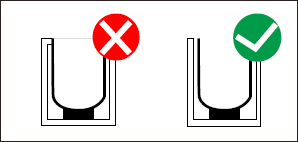

Avoid premature crucible failure by ensuring that the furnace drain hole is sealed.

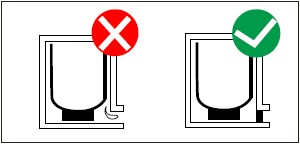

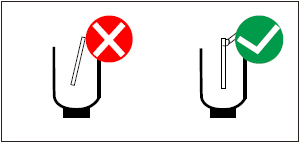

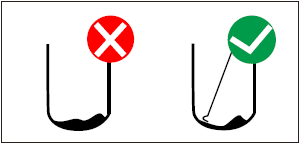

For lift-out,tongs must be placed on lower third of crucible fit tongs evenly on both sides.

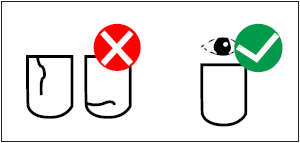

Check for cracks or transport damage before use.

Base block must be fiat ,larger than crucible bottom and centered.

Ingots should be placed carefully into the cruible,using tongs.

Empty curcible before removing from furnace.Do not let metal Solidify in crucible

Clean carefully everyday while still hot.

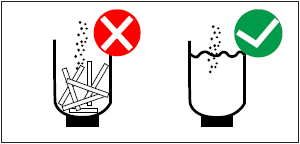

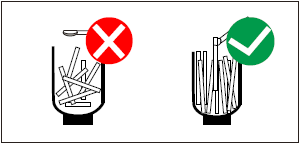

Put in returns scrap first. then add ingots vertically

Crucible Heating Recommendation

Preheating Process for Crucible First Use:

1.First,after installation in the furnace the crucible should be heated up slowly to a temperature of 200C over a period of 2 hours,in order to eliminate any moisture that may be present.

2.Subsequently,the crucible should be heated up to 600 C on low power over a period of 1.5hours,to ensure the glaze and crucible material can be sintered and formed into aadditional anti-oxidation coating,which is essential to achieve the maximum possible crucible life.

3.Finally,the full heating rate is used to reach 920C over halt hour, the temperature of 920 C should be held for approximately 1 hour,then add the ingots into crucible.

4.preheating curve as shown in the Green line.

Preheating Process for Crucible After First Use:

1.First,the crucible should be heated up slowly to a temperature of 600 C over a period of 2hours, in order to eliminate any moisture that may be present and to ensure the glaze and crucible material can be sintered to avoid the crucible material be oxidized.

2.subsequently,the full heating rate is used to reach 920 C over half hour,the temperature of 920c should be held for approximately 1 hour,then add the ingots into crucible.

3.Preheating curve as shown in the Red line.